infotx@cpt.eurofinsus.com |

(512) 243-6426

ASTM E2315 Suspension Time-Kill Test

ASTM E2315 Suspension Time-Kill Test

The suspension time-kill test is excellent for topical antiseptic product developers because it is a fast, relatively inexpensive, and reproducible way to measure the biocidal potential of a liquid antimicrobial formulation. It consists of directly inoculating a liquid test substance with a high concentration of test microorganisms and then determining the percentage killed over time.

The suspension-based time-kill test has been standardized by ASTM International, as ASTM E2315 - "Standard Guide for Assessment of Antimicrobial Activity Using a Time-Kill Procedure."

ASTM E2315: PROCEDURE AT A GLANCE

- A microbial culture is prepared. For most bacteria, a 24 hour culture in nutrient broth works well. For most fungi, a spore preparation from a saline wash of an agar plate or slant works well.

- Equal volumes of the test product are placed in sufficient sterile test vessels - enough to account for all replicates that will be performed.

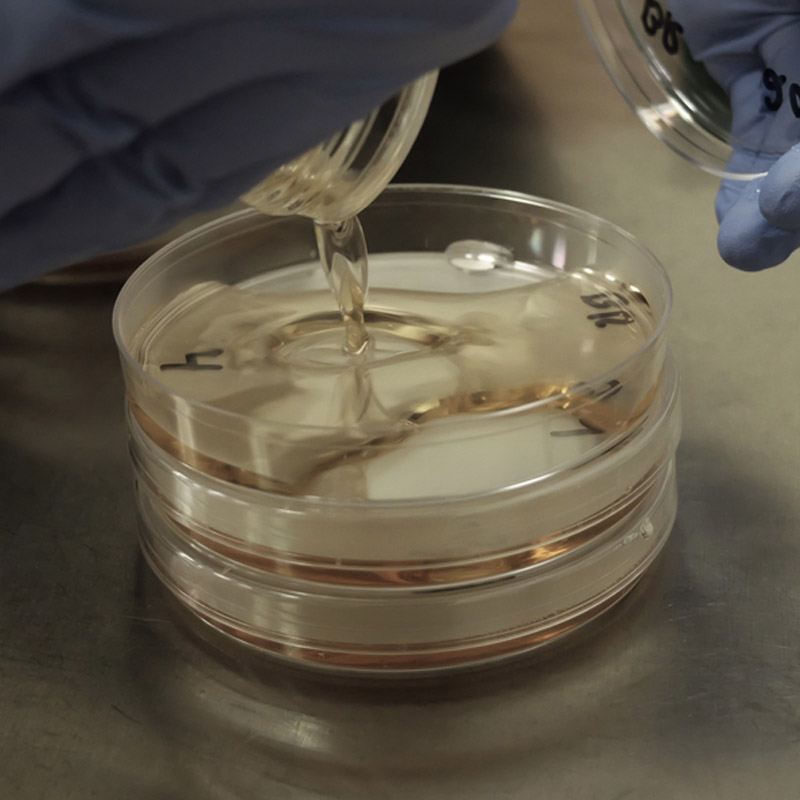

- A volume of microbial culture (usually 1/10 or less of the product volume) is placed in the test vessel and then immediately mixed.

- After the predetermined contact time(s), small aliquots of the mixture of bacteria and product are removed, chemically neutralized, and microorganisms are enumerated.

- To measure initial microbial concentrations, a saline control is spiked with the same microbial culture and then enumerated.

- Numbers of microorganisms in the reaction vessel are plotted over time.

- Neutralization controls are run as appropriate.

Strengths of the Suspension Time-Kill Test

- The impact of a topical antiseptic product on microorganisms over time (otherwise known as a death or kill curve) can be studied with relative ease using this suspension-based method.

- Suspension-based time-kill tests are relatively inexpensive.

- The test parameters for suspension-based time-kill tests are easy to control in the laboratory setting, so comparisons can be made fairly easily between various products tested under the same conditions.

- The suspension-based time-kill test involves exposing microorganisms to excess product in a liquid setting, so the test is a fitting model system for instances in which antiseptics will be used in large volumes to kill microorganisms (such as with submersion of hands into an antiseptic bath or for extended exposure rinses).

- Very brief contact times can be studied with relative ease.

Weaknesses of the Suspension Time-Kill Test

- The test method is difficult to relate to inactivation of microorganisms on the surfaces of human hands or other similar substrates.

- It is somewhat of a "best case" method, meaning that good percent reductions are likely to be seen if the test product is indeed antimicrobial and the contact times are sufficient.

- The way in which the microbial inoculum is prepared can have an impact on the test outcome, since different broths or suspensions may interact with or inactivate antiseptics.

ASTM E2315: EUROFINS CRL’S EXPERTISE

Eurofins CRL was founded in 2017 as a collaborative effort between two specialty contract testing facilities. ECRL combines the expertise derived from its legacy with the innovative methods and quality focus that makes the Eurofins name a leader in third-party testing world-wide.

Eurofins CRL Is:

A contract testing laboratory designed to support the hand hygiene and infection control industry. Testing is carried out in compliance with current FDA, Good Laboratory Practice (GLP), and Good Clinical Practice (GCP) regulations by skilled, experienced microbiologists and chemists, to quickly meet your project testing goals.