infotx@cpt.eurofinsus.com |

(512) 243-6426

CHG Compatibility Testing

Chlorhexidine gluconate (CHG) is a widely used active ingredient found in many pre-operative skin preparation and health care personnel hand sanitizer formulations. Chlorhexidine's antibacterial properties are understood to be a result of positively charged chorhexidine salts binding to negatively charged bacterial cell walls. Another benefit of CHG's positively-charged molecule, is its ability to remain on the skin surface and impart persistent antimicrobial efficacy to its users.

Because the positive charge of this active ingredient is critical to its persistent antimicrobial efficacy, it is critical that treatment with subsequent products does not deactivate the CHG charge. Deactivation of the CHG charge results in deactivation of it's antimicrobial efficacy. CHG can become deactivated into insoluble salts when combined with negatively charged compounds, including the anionic thickening or emulsifying components of many leave-in products, including alcohol hand sanitizers.

ECRL offers both nonclinical and clinical testing options for CHG-based skin antiseptic manufacturers to understand their formulation's compatibility with other products, such as topical handrubs.

Using a nonclinical study design, a surrgoate skin surface (such as porcine ventral epidermis or VITRO-SKIN, a synthetic skin substrate) may be used to mimic the human skin surface. Using a clinical study design ECRL can also recruite human subjects to apply both the CHG-based product and other products to determine compatibility via evaluation of antimicrobial efficacy.

Testing Details

As with any clinical or non-clinical microbiological study, the observed CHG compatibility of your product can be significantly impacted by a wide range of variables, including substrate preparation steps and methods of CHG reservoir development. Eurofins CRL has performed thorough internal testing to confirm that it's methods of CHG compatibility testing are reproducible, scientifically defensible, and accurate. ECRL's internal testing was based on extant literature such as Kaiser et al., “Inactivation of chlorhexidine gluconate on skin by incompatible alcohol hand sanitizing gels.”

Product Categories – Immediate, Residual, and Persistent Efficacy Evaluations

CHG compatibility can be evaluated in terms of either residual, persistent, or immediate efficacy.

Evaluations of residual efficacy require the generation of a CHG reservoir on the substrate (human hands or human skin substitute) used for testing. After reservoir generation a subset of substrate carriers are inoculated with a test microorganism and then harvested, providing a demonstration of CHG efficacy by itself. Another subset of carriers is treated with the test product, inoculated, and harvested to provide a determination of compatibility. A final subset of carriers, which was not exposed to the CHG product or the test product, is inoculated and harvested to act as a control, to which the other two subsets are compared.

Evaluations of persistent efficacy require an assessment of the normal microbial flora of subject before and after treatment, and can be achieved by retaining a “control” hand and a “test” hand on each subject for the duration of testing.

Immediate efficacy retains the same control as residual efficacy. However, the rest of the testing is performed quite differently. The efficacy of CHG alone is evaluated by inoculating an untreated substrate carrier and allowing that inoculum to dry. After drying the CHG product is applied and harvested after a brief contact time (typically less than 1 minute). Product compatibility is established on another set of carriers, which are treated with the test product, then inoculated, and then finally treated with CHG and harvested after the same contact time.

Picking the Best Carrier Substrate

Choosing the correct carrier substrate for CHG compatibility testing can be crucial to the success of your study.

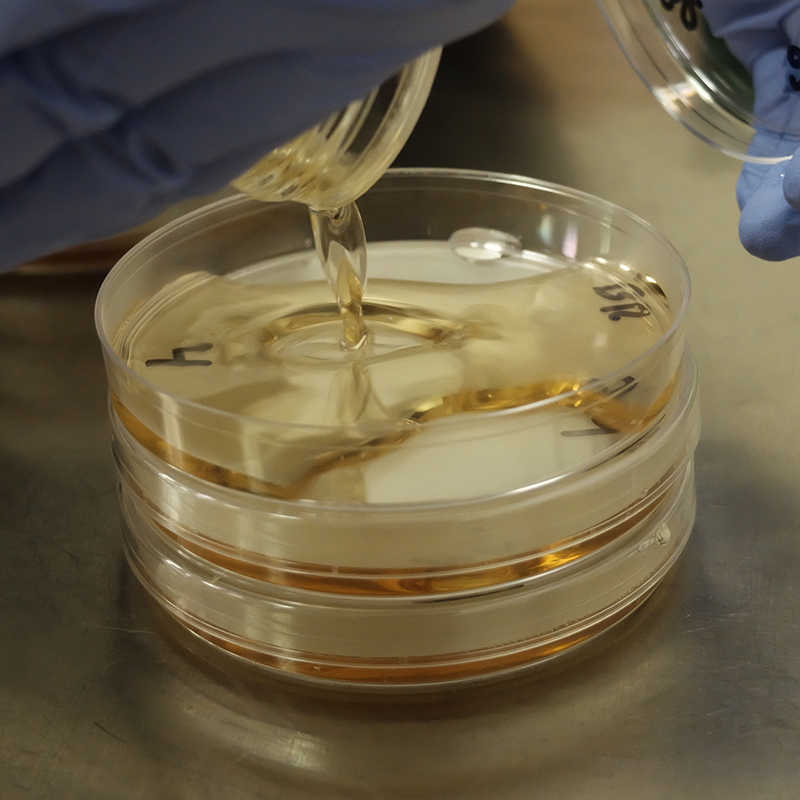

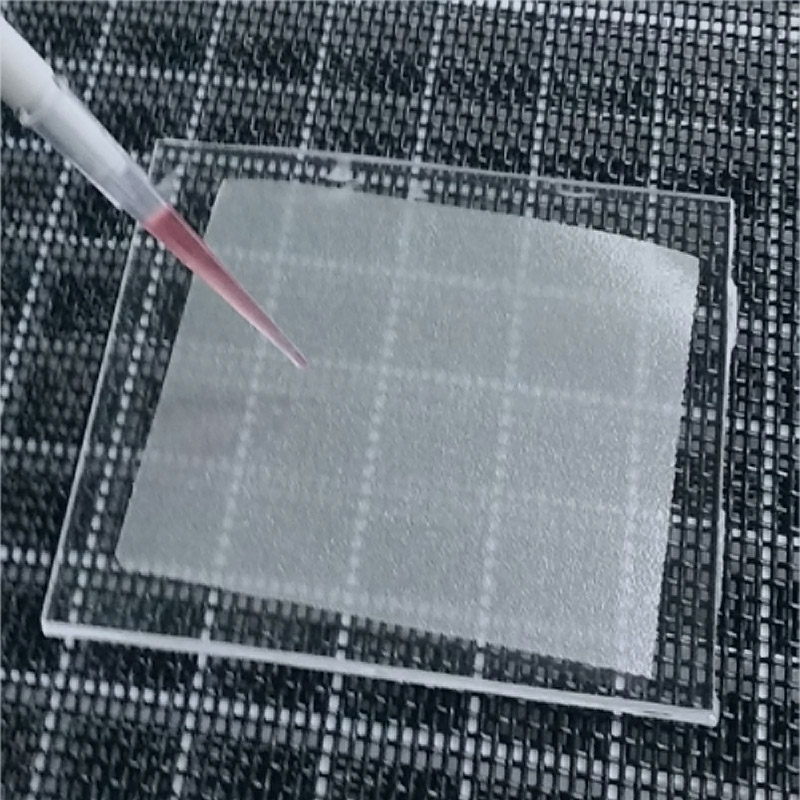

Porcine ventral epidermis (pig skin) is a classic carrier for this type of testing – it is comparable to human skin in its biochemical and histological properties. Various studies examining CHG compatibility1,2,3 with leave-on products consider pig skin to demonstrate comparable properties to human skin during testing, and to demonstrate comparable efficacy results as well. The value in using pig skin as a testing model is its ability to mimic a variety of skin contamination and treatment conditions.

VITRO-SKIN, a synthetic skin substrate, provides an alternative to pig skin. VITRO-SKIN is provided by its manufacturer in a dehydrated condition and is rehydrated by Eurofins CRL directly prior to each use. Once hydrated, the topographical side of the skin is used for CHG compatibility evaluations. VITRO-SKIN is most commonly used for SPF measurement and UV transmission testing and was developed to mimic the surface properties of human skin, including tophoography, pH, surface tension, and ionic strength.

A side by side comparison of these two substrates is included below. Each study sponsor is encouraged to discuss their product goals with Eurofins CRL prior to making a decision about the best substrate for their test product.

1. Inactivation of chlorhexidine gluconate on skin by incompatible alcohol hand sanitizing gels. Kaiser N., Klein D., Karanja P., Greten Z., and Newman J. 2008.American Journal of Infection Control.

2. Inactivation of Residual CHG Activity by Thickened Alcohol Solutions. Greten Z., Klein D., Kaiser N., Thompson A., and Dell’Aringa B. 2004. American Journal of Infection Control.

3. The Effects of Surfactant Systems and Moisturizing Products on the Residual Activity of a Chlorhexidine Gluconate Hand Wash Using a Pigskin Substrate. Benson L, LeBlanc D, Bush L, White J. 1990. Journal of Infection Control and Hospital Epidemiology.